C SERIES

The Cyclone Filter is Built In

This is a YTH Basic Series

C SERIES

The Cyclone Filter is Built In

This is a YTH Basic Series

Large flow All-in-one Low-pressure coolant pump

This is a YTH corresponding to large flow and low pressure with cyclone filter. YTH-CI enables operators to be free from troubles and filter maintenance around a coolant tank because of automatic clean-up system by cyclone filter.

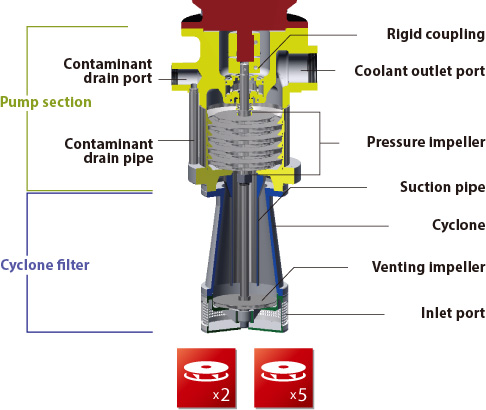

| Cyclone filter The cyclone system sorts out chips from the coolant fluid. |

|

| Impeller pump Centrifugal mechanism generates pressure to supply a large flow coolant. This is a large flow transfer pump |

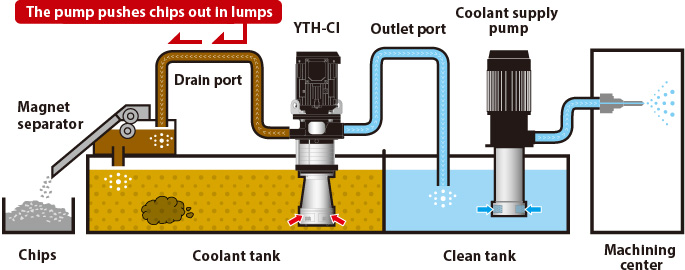

YTH-CI transfers filtered coolant from a coolant tank to an isolated clean tank. Filtered coolant is supplied to machining centers by High-Medium pressure coolant supply pumps. Chips and contaminants are pushed out from YTH-CI and collected by magnet separator or sedimentation tank.

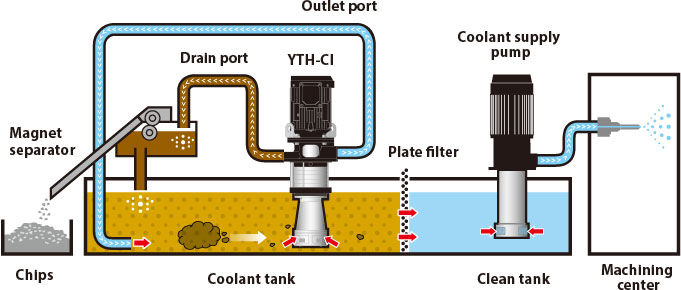

YTH-CI can totally clean up a coolant tank by circulation flow. At the same time, YTH-CI also automatically backwash plate strainers between a coolant tank and a clean tank by suction of dirty coolant, which reduces maintenance work for backwash plate dramatically.

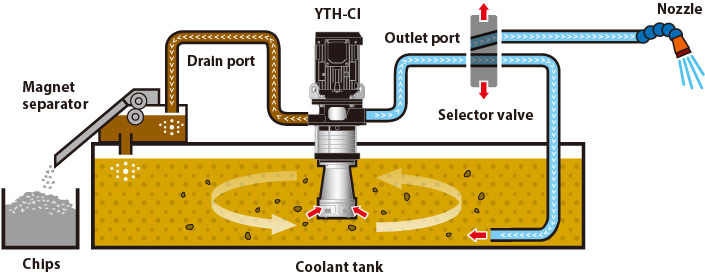

YTH-CI supplies filtered coolant to nozzles in a machinery tool. When the machinery tool stops metal cutting operation, YTH-CI automatically switches to cleaning of a coolant tank by circulation flow.

【YTH-CI –the All in one coolant unit】

TOP-YTH ①②-③C

| ① Motor capacity | 1500 : 1.5kW |

|---|---|

| 3700 : 3.7kW | |

| ② Motor type | AC : AC 200/200/220/230 V 50/60/60/60 Hz 3 phase electric induction motor (IE3) with CE marking |

| ③ Flow rate * | 50Hz | I155 : Impeller pump (5 stages/150l) |

|---|---|---|

| 60Hz | I152 : Impeller pump (2 stages/150l) | |

| 50Hz | I305 : Impeller pump (5 stages/300l) | |

| 60Hz | I302 : Impeller pump (2 stages/300l) | |

| Filtering method | C : cyclone type | |

* I155・I305 is not applicable to 60Hz

| Model | Motor capacity(kW) | Flow rate (ℓ/min) | Total pump head (m) | Approximate weight (kg) |

|---|---|---|---|---|

| YTH1500AC-I155C (50Hz) | 1.5 | 150 | 55 | 43 |

| YTH1500AC-I152C (60Hz) | 40 | |||

| YTH3700AC-I305C (50Hz) | 3.7 | 300 | 55 | 70 |

| YTH3700AC-I302C (60Hz) | 40 | 69 |

Unique reversed cyclone filtration system enables to separate clean coolant and contaminants. Contaminants are pushed up through side surface of cyclone filter by centrifugal force and discharged. Clean coolant are collected to center of cyclone filter and boosted up by multiple-stage impellor pump.

| Material | Iron | Casting | Aluminum | Copper |

|---|---|---|---|---|

| Compatibility | Excellent | Excellent | Good | Excellent |

| Suction strainer | 3mm (Solids larger than this must be removed from the tank) |

|---|---|

| Cyclone filter | Water soluble coolant 100 µm: 99.9% (specific weight 2.7) Straight oil 100 µm: ≤80% (specific weight 2.7) |